I am interested in your services

We are always looking for new challenges and opportunities to help our clients succeed. If you're searching for a reliable and innovative engineering partner, let’s get in touch.

Contact usExcellence, Every Step. Quality Assured. Welcome to LION Engineering.

Our quality assurance service meets the highest industry standards and customer expectations. Using a comprehensive quality control process, we identify and address any defects or issues before they affect the end user.

At LION Engineering, quality isn't just a goal; it's our cornerstone. With an unwavering commitment to excellence, we uphold the highest standards of quality assurance throughout every facet of our operations. Our ISO 9001 certified Quality Management System serves as the bedrock of our commitment, ensuring that every process, product, and service meets stringent quality benchmarks.

Central to our dedication to quality is our team of dedicated and extensively trained quality inspectors. These professionals are equipped with the latest tools and techniques to meticulously scrutinize every aspect of our operations, leaving no room for compromise. Their expertise, combined with our modern inspection equipment, enables us to deliver products and services of unparalleled precision and reliability.

Embracing modern quality practices such as 5S, we continuously strive for efficiency, consistency, and improvement in everything we do. By fostering a culture of continuous improvement and empowerment, we empower every member of our team to contribute to our collective pursuit of excellence.

At LION Engineering, quality isn't just about meeting standards; it's about exceeding expectations. Our customer-centric quality and performance culture ensure that every product and service we deliver not only meets but surpasses the highest levels of customer satisfaction. With a relentless focus on quality, we stand ready to exceed your expectations at every turn

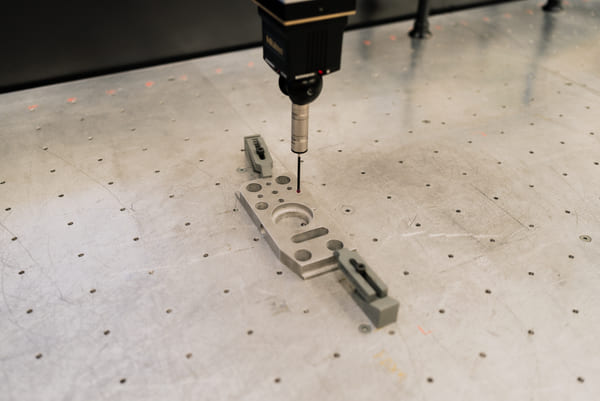

At LION Engineering, precision is our priority. Our dedicated metrology lab is well equipped to provide enhanced levels of inspections, including precision surface tables, temperature control systems, and calibrated inspection tools. With meticulous attention to detail, we ensure every component meets the highest standards of accuracy and reliability, guaranteeing quality in every aspect of our work.

LION Engineering utilizes Trimos digital height gauges for precise and efficient height measurements. These advanced instruments ensure accuracy and reliability in our dimensional inspections, enhancing our quality assurance processes. Trusted for their precision and ease of use, Trimos height gauges play a crucial role in maintaining our commitment to excellence in every aspect of our work.

LION Engineering utilizes specialist Gagemaker equipment and thread gauges to API specifications for rotary inspection, ensuring precise measurements. These specialized tools guarantee accuracy in assessing critical thread parameters, maintaining product integrity. Woking in accordance with API standards, we reinforce our commitment to excellence and safety in all operations.

LION Engineering leverages cutting-edge technology like the large capcity Mitutoyo CrystaApex CMM for precise and efficient dimensional measurement. With its advanced capabilities and accuracy, this state-of-the-art Coordinate Measuring Machine ensures that our products meet the most exacting specifications. Trusted for its reliability and performance, the CrystaApex CMM plays a crucial role in our quality assurance process.

LION Engineering trusts Sonatest Ultrasonic Testers for reliable and accurate non-destructive testing. These cutting-edge instruments ensure the integrity and quality of our materials and components through precise ultrasonic inspections. With their advanced features and user-friendly interface, Sonatest Ultrasonic Testers empower us to maintain the highest standards of quality and safety in our operations.

LION Engineering prioritizes the training of our quality inspectors, empowering them to conduct dimensional and non-destructive testing (NDT) inspections effectively. Our inspectors are proficient in performing precise measurements and NDT examinations, both onsite and in the field. This comprehensive training ensures that we deliver top-quality inspection services tailored to our clients' needs, wherever they may be.

The Mitutoyo shadow graph is a vital tool in LION Engineering's arsenal for precise optical measurement. With its ability to swiftly and accurately measure intricate components, this innovative equipment ensures the integrity and precision of our products. Trusted for its reliability and versatility, the Mitutoyo shadow graph plays a pivotal role in our quality assurance process, empowering us to deliver superior results with confidence.

LION Engineering relies on Faro inspection arms for precise, portable measurements, both on the production floor and in the field. These advanced tools offer flexibility and accuracy, ensuring superior quality wherever we operate. With real-time feedback capabilities, they enhance our efficiency and maintain our commitment to excellence.

Interested in learning more about our certifications? View all the documents and get the information you need.